EDGECAM Software

EDGECAM is a world leader in CAD/CAM software with a proven track record of reliable product delivery.

EDGECAM is a world leader in CAD/CAM software with a proven track record of reliable product delivery.

Intelligent CAM Software for Milling, Turning, Mill-Turn Machining, Multi Axis Machining, and Wire EDM. EDGECAM creates efficient, reliable toolpaths with precision and control for the production machinist and include the following applications: EDGECAM Mill / Turn; EDGECAM Milling; EDGECAM Turning; EDGECAM Waveform; EDGECAM Wire EDM; EDGECAM WORKXPLORE; EDGECAM Inspect; EDGECAM Intelligent Manufacturing; EDGECAM Designer; EDGECAM Manufacturing Asset Management.

Major enhancements in EDGECAM 2022.1 include: Holder collision avoidance, advanced 5-axis deburring cycle, tombstone manager, thread milling, machine tool configuration improvements, automatically set stock and fixture attributes from DESIGNER, waveform roughing – multiple enhancements, waveform turning, rough grooving cycle and machine simulation.

The TestDrive Programme has been designed to give CNC Manufacturers the chance to evaluate the use of a CAM system with zero cost and at zero risk. A number of engineering firms are falling behind their global competitors by still relying on manual programming, or use inefficient CAM software to create CNC code.

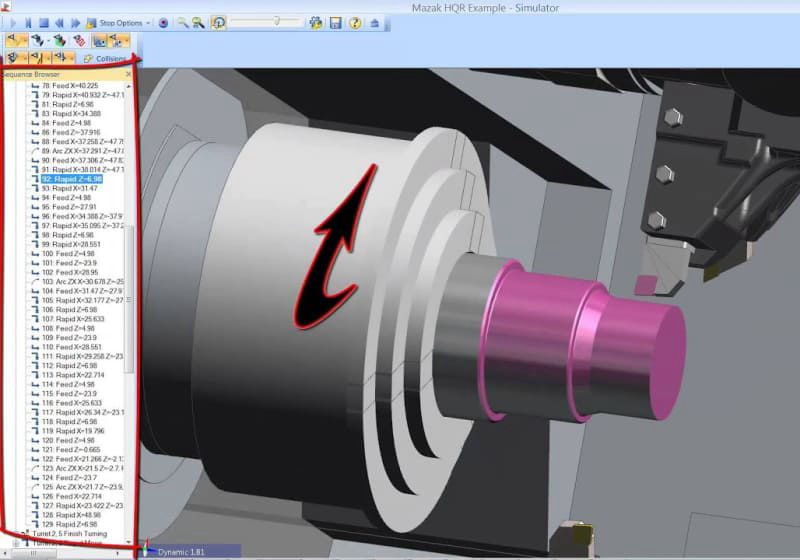

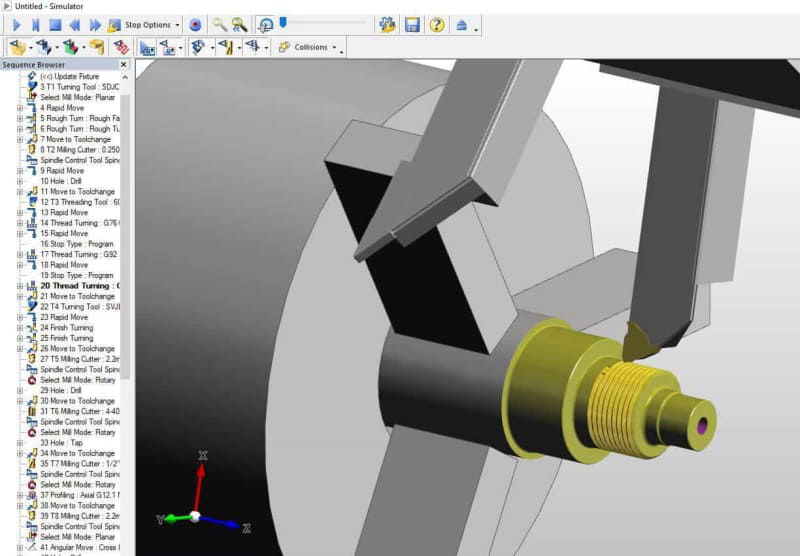

The use of tail stocks, steady rests, sub spindles, twin turrets along with C Axis, CY Axis and B Axis are regular features on today’s Multi-Task machine tools. In this collision rich environment, the programming of these machines is made simple and safe utilizing EDGECAM’s turning and milling combinations in a single environment.

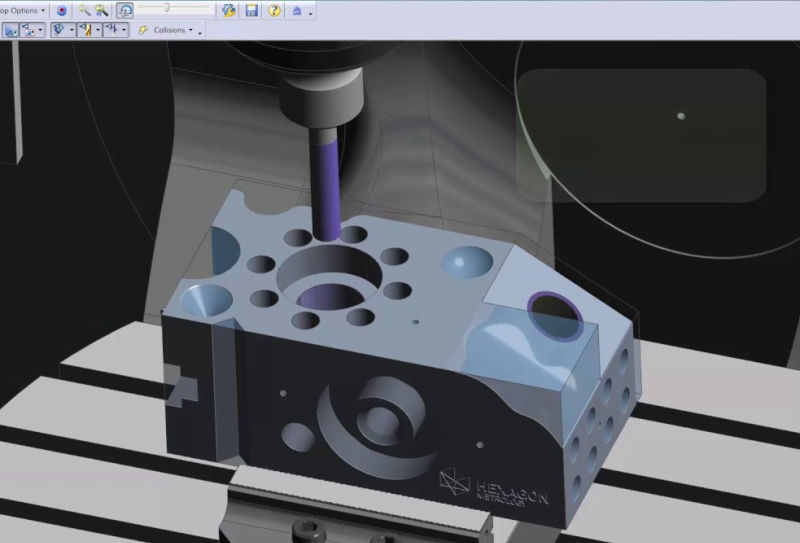

With the addition of 4 and 5 axis simultaneous milling, the simulation of these machine tools is made even easier.

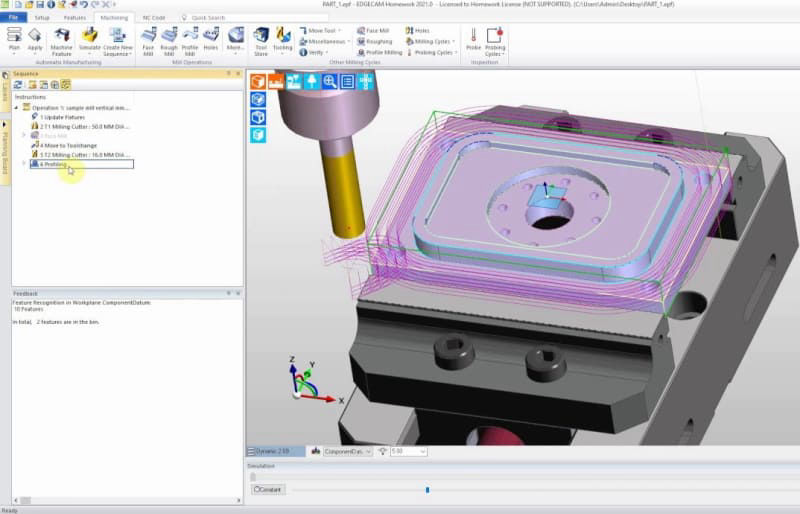

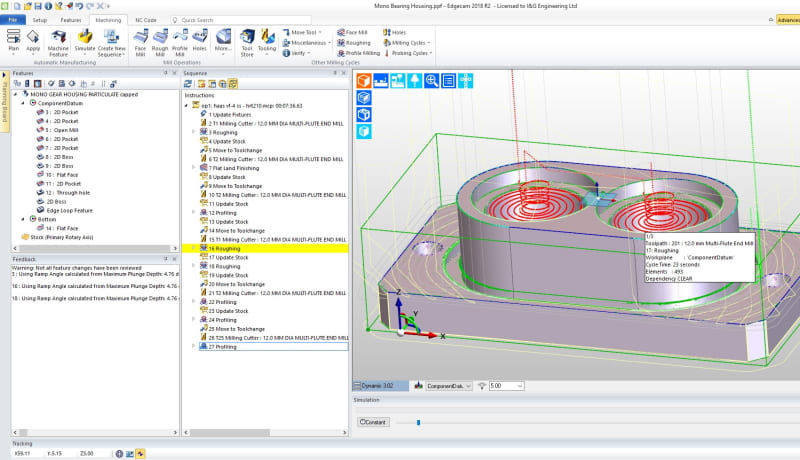

EDGECAM Milling provides functionality to program wire frame geometry or solid model component parts on a variety of machine tool configurations, from 2.5 Axis milling to complex surface tool paths on 3 to 5 axis milling machines. EDGECAM seamlessly integrates 4 and 5 axis simultaneous machining within its milling and mill/turn environment to allow a range of multiaxis cutting strategies to be applied to the most complex tooling or components.

EDGECAM offers intuitive dialogues making programming simple for the new user and comprehensive tool path control for advanced requirements.

EDGECAM Turning provides functionality for a wide range of machine tools, including 2-Axis lathes, multi-turret configurations, sub-spindle turning centres and mill/turn machines. EDGECAM fully supports turning centers including Bar Pull and Feed, Part Pick Off, Balanced and Mirrored Turning, and Turret Synchronization.

Waveform machining is included on EDGECAM Licensees at the Standard and higher product levels, no additional purchase necessary.

Waveform maintains a constant chip load for high speed machining. The tool moves in a smooth path to avoid sharp changes in direction, maintaining a constant/high feedrate.

Waveform machining is available for both Milling and Turning operations.

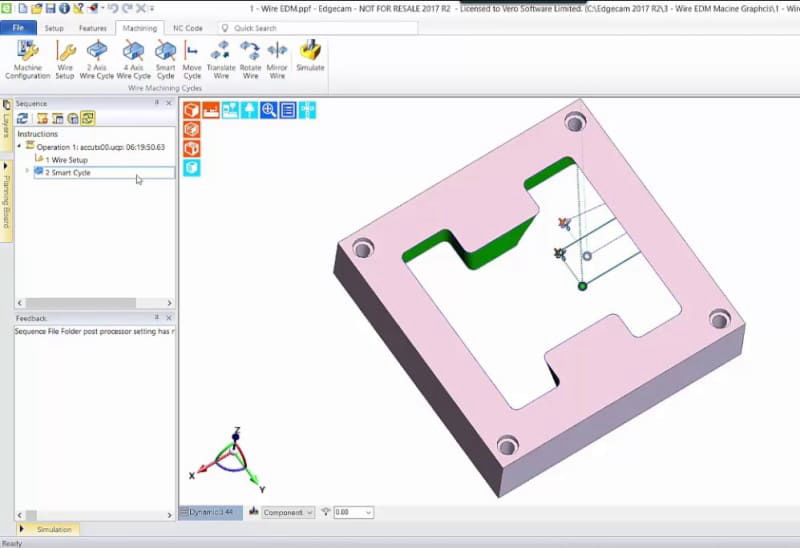

EDGECAM Wire EDM provides the flexibility and confidence to manufacture 2 and 4 axis parts accurately and efficiently. Advanced functionality enables manufacture of complex shapes with irregular tapers easily.

EDGECAM WORKXPLORE is the ideal tool for directly displaying and evaluating 3D CAD files without the need for the original CAD application. The intuitive, easy-to-use interface enables novice and experienced users alike to explore any type of 2D/3D CAD file.

A wide range of CAD interfaces are available: Catia V5, Catia V4, Unigraphics, Parasolid, Pro/E, SolidWorks, Solid Edge, Cadds, IGES, STEP, Unisurf, STL (binary and ASCII), VRML, ISO toolpaths, DXF, DWG, HPGL. Please note that it is possible to load GD&T data from the CAD interfaces that support geometric tolerancing.

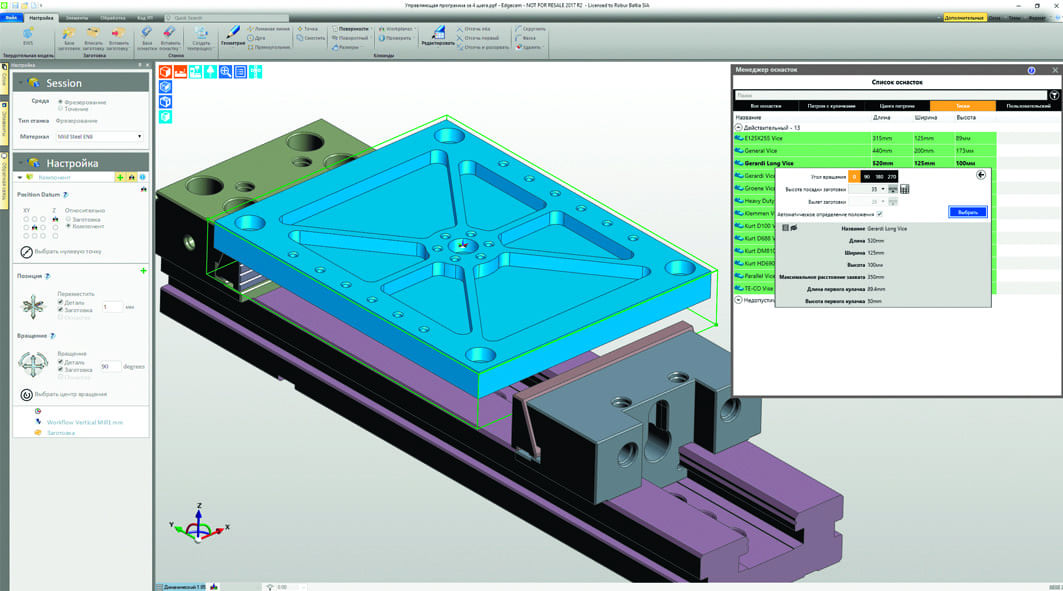

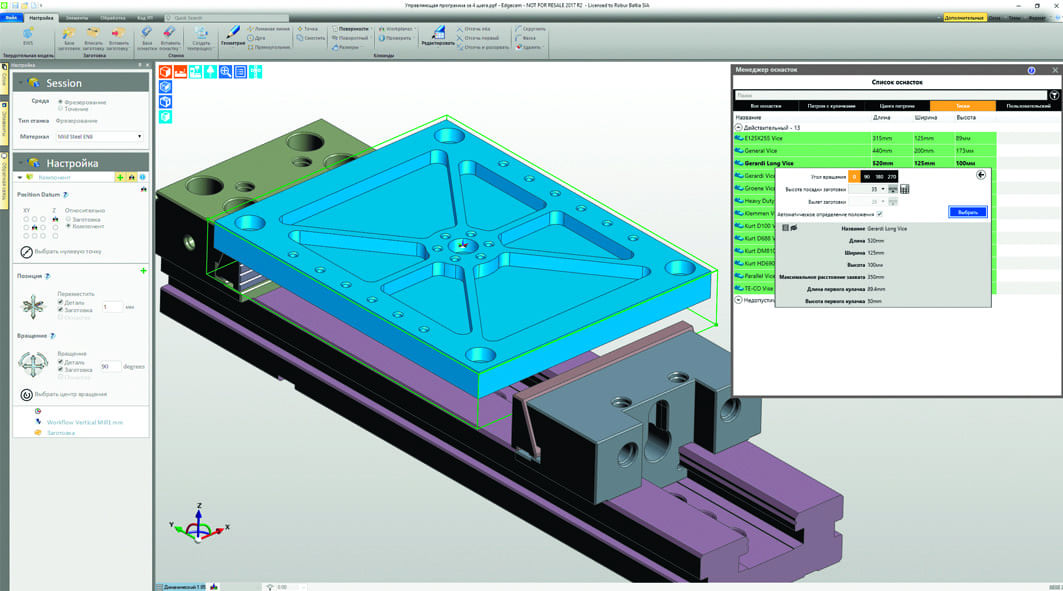

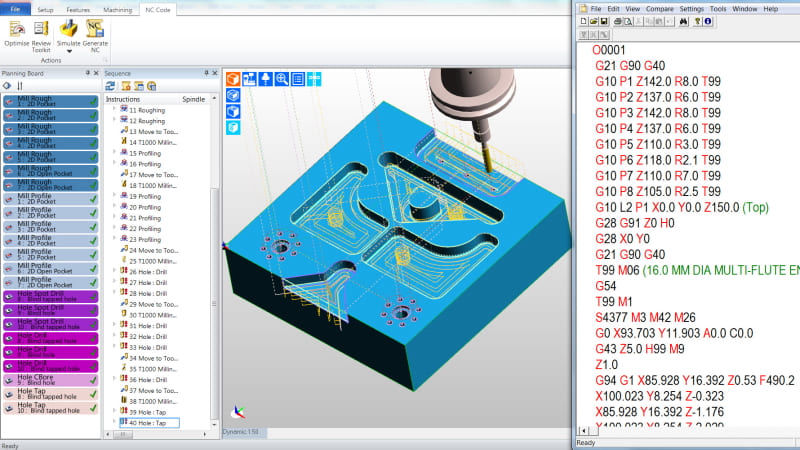

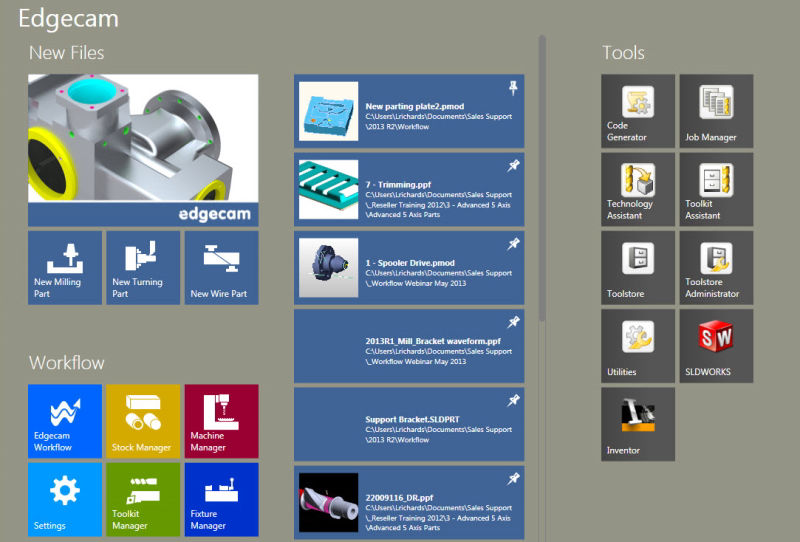

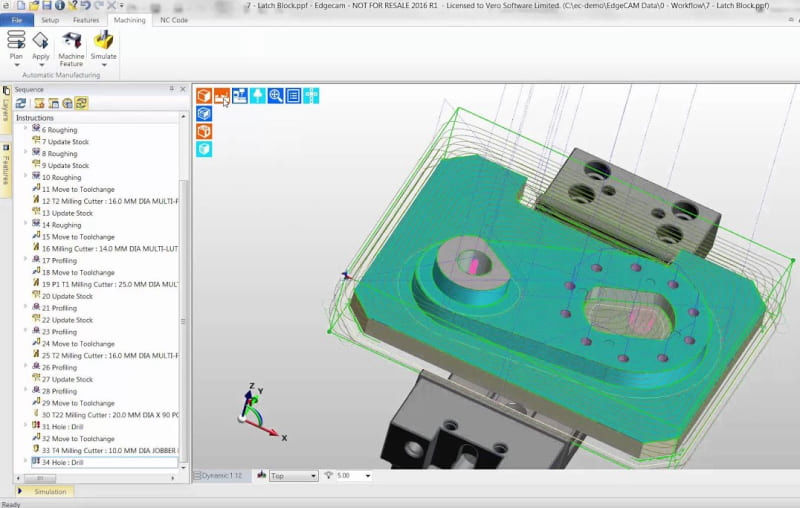

Designed for manufacturers to reduce costs, improve quality and hit shorter lead times. Operators will be able to apply toolpaths to prismatic parts in minutes. Accelerated generation of CNC code: EDGECAM Workflow understands the component topology and the required manufacturing environment therefore accelerating toolpath generation.

Workflow will have a significant impact on shortening programming time, and because it is so simple to operate, the learning curve for new users is considerably reduced.

EDGECAM Inspect combines the Hexagon industry leading metrology tools and know-how, with Hexagon cutting edge manufacturing expertise.

EDGECAM Inspect is a full featured, easy to use solution for users wanting fast creation of on machine measurement cycles with quick, efficient tool path creation and generation of reliable, measurement results.

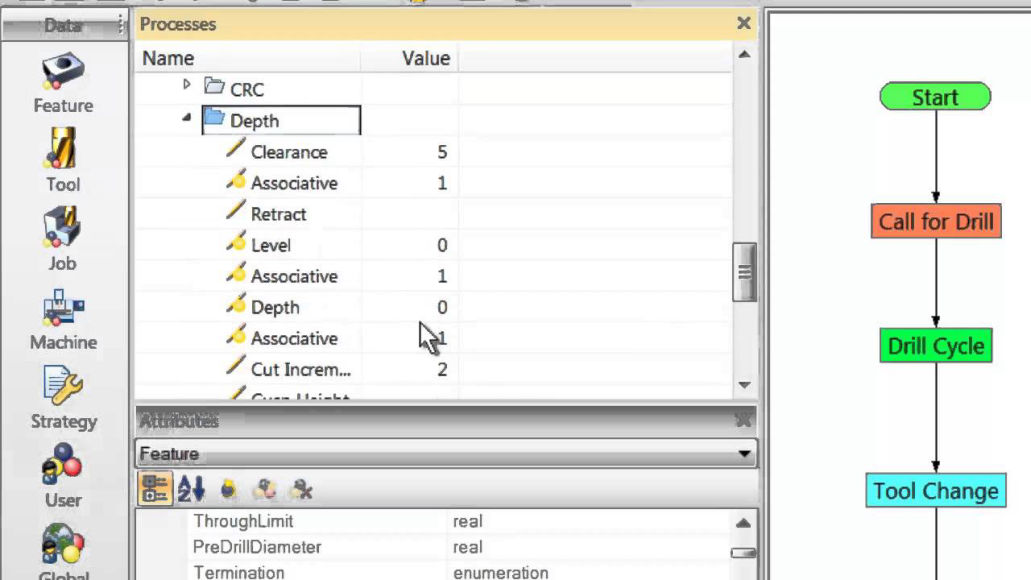

EDGECAM Strategy Manager encompasses the best from the principles of rules, knowledge and feature based machining and utilizes these to produce a fast, reliable and highly automated solution for solids machining.

Reduce your programming time to seconds with EDGECAM Strategy Manager and

can be used to automate any EDGECAM machining application.

Advanced CADCAM Software Solutions For The Manufacturing Industry

With EDGECAM Solid Machinist, the integrity of your design is maintained because the solid model is imported without translation. EDGECAM Solid Machinist uses automatic feature recognition to interrogate the model geometry and quickly identify machinable features.

The intelligent CAD application that combines sophisticated capabilities with simplicity and usability. DESIGNER’s powerful design and detailing capabilities open up new possibilities for smarter manufacturing to a wide range of manufacturers.

The CAD application perfectly balances powerful design and detailing capabilities with ease of use. Even new users can easily harness DESIGNER’s wide variety of functions to successfully execute and optimise design for manufacturing projects.

Hexagon’s solution for industrial IoT device monitoring enables you to monitor the performance, availability and health of your manufacturing assets through the SFx platform.

A reliable and effective IoT asset performance monitoring solution is critical in keeping equipment connected, up-to-date, secure and at operating its fullest potential. Hexagon's Asset Management solution connects relevant systems and processes to maximise equipment effectiveness.

By filling out this form, you accept the terms of the Agreement on the use of the site, including with regard to the processing and use of personal data

Built with

Free Website Software