Use any number of functions for measurement and automatic part setup. For instance: Bores, Contructed Points, or Mid-points.

Thanks to the dialog-based interactive teach-in method, the machine user can easily create measurement cycles without any macro programming knowledge.

Effective use of 5 axis machines requires quick measurement and setup of workpieces. This is easier than ever with m&h NC Gage, regardless of which 5 axis kinematic-type is used for machining and measuring.

Use Mobirise website building software to create multiple sites for commercial and non-profit projects.

NC Gage is designed for use on modern multi-tasking machines and supporting challenging machining tasks. Special functions simplify adding fully automated gauging, setup and inspection to multi-spindle processes.

Quickly identify and easily correct kinematic errors. The option CheckSet5 offers the possibility to analyse the motion of the rotation axes on 4 and 5 axis milling machines.

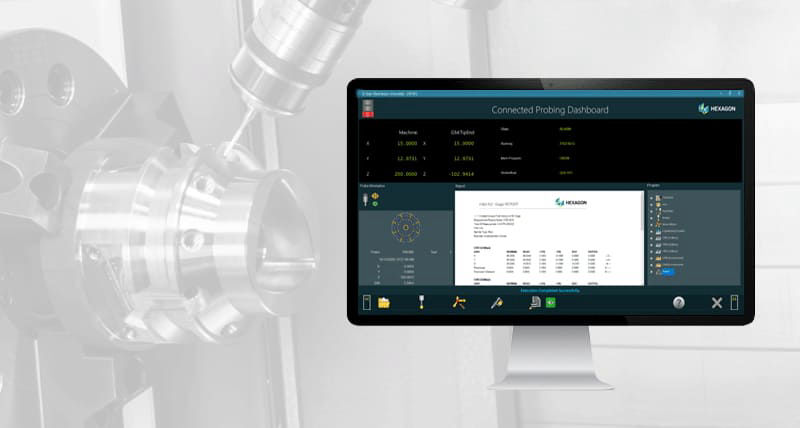

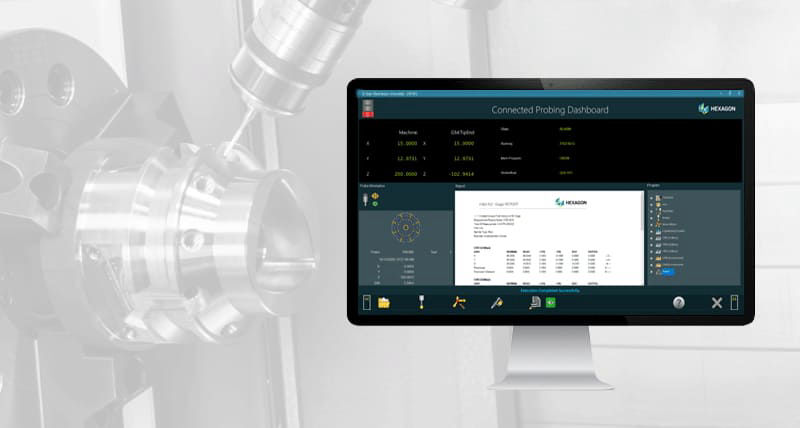

m&h NC Gage produces clear and concise measurement reports similar to those from a CMM. Color-coded results for in/out of tolerance as well as a simple tolerance overview scale provides the operator with the information needed at a glance.

Measurement Reports can be saved automatically or printed, and serve as documentation of the quality produced. A statistics interface is also included allowing output to Q-DAS, Excel and XML.

By filling out this form, you accept the terms of the Agreement on the use of the site, including with regard to the processing and use of personal data

Designed with Mobirise

HTML5 Generator