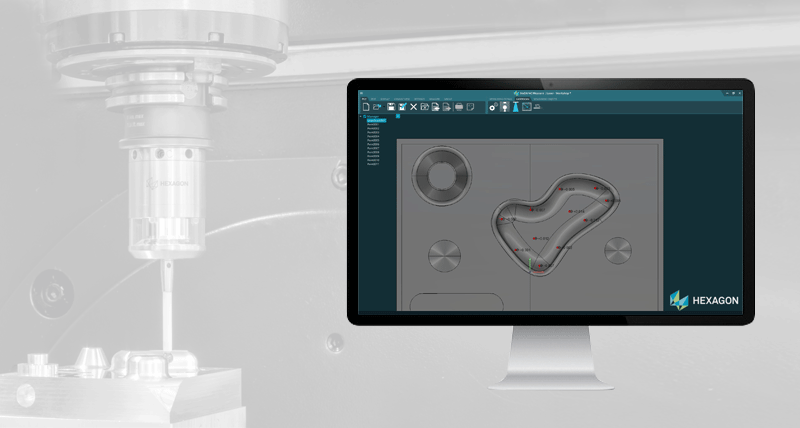

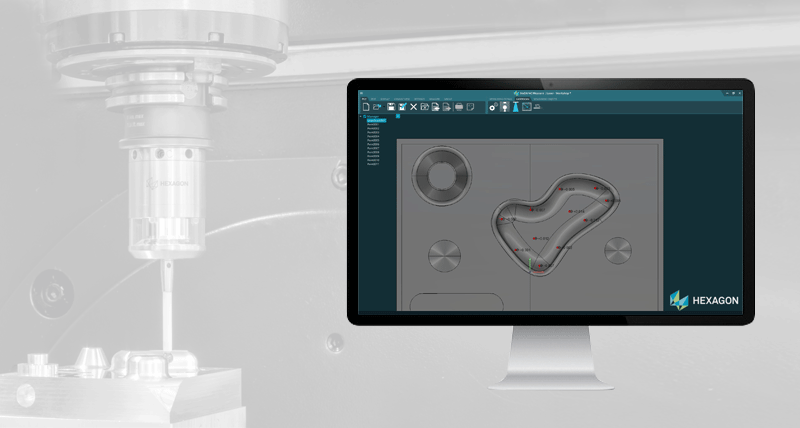

HxGN NC Measure | Core – Key measurement programmes

The Core version allows users to create key measurement programmes by selecting single points on the CAD-model. Those models can be imported IGES- or STEP-formats.

The Core software enables the import and export of measurement programmes, as well as the creation of a basic report in ASCII-format following the completion of measurements in the machine tool, .

For precise results, calibrations are executed with 160 points on a calibration sphere. To avoid damage during measurements, a graphical collision control can be simulated before execution.

Projects in Hexagon’s 3D Form Inspect Software (MHI-format) are fully compatible with HxGN NC Measure, thereby ensuring accurate data transfer.

HxGN NC Measure | Report – Detailed measuring reports and protocols

HxGN NC Measure | Report tailors the presentation of results to users’ and customers’ specific, with different templates and file formats available.

Users can alter tolerances and colour scales and save reports in Excel, Word, pdf, 3D-pdf or ASCII formats. Protocols can be exported in the form of PC-DMIS, including deviation bars, as well as to Q-DAS Software.

HxGN NC Measure | Best-Fit Pro – Fast and reliable part alignment

Correctly positioning parts in the machine tool clamp often requires several manual steps and takes a lot of time. The HxGN NC Measure | Best-Fit Pro module makes this process much easier and faster by creating correction values that can be loaded to the machine control for automatic part adjustment.

HxGN NC Measure | Laser – Dedicated software module for laser scanning on machine tools

Capturing complete point clouds on machine tools has never been easier. HxGN NC Measure enables users to rapidly generate measurement data for the complete surface of the part and gain insight into the part’s quality and exact position

Results can be viewed as a colour map super-imposed on the digital CAD model of the part, while it is still clamped on the machine tool.

The software also makes it simple to create measurement reports for further analysis or for use in later production steps.

HxGN NC Measure | 5 Axis - Full support of the 4th and 5th axes

Modern machine tools can use the 4th and 5th axes to enable the production of almost infinite forms , while saving time by doing away with the need to reclamp parts on the machine. However, limitations arise when only the X,Y- and Z-axes of a machine tool can be used for measurement. Even when using complex styli configurations, it is not always possible to reach all areas of a part to check the dimensions.

With the software module HxGN NC Measure | 5 Axis, users can perform measurements and laser scans sidewise, thereby using all five axes with only a couple of mouse clicks. It enables the capture of more valuable and detailed data in less time, especially when scanning a part with laser scanners.

HxGN NC Measure | NCG Connect - Export- and import module for m&h NC Gage

HxGN NC Measure | NCG Connect enables offline programming for the innovative measurement app NC Gage. Users can benefit from the easy-to-use interface in HxGN NC Measure and at the same time deploy the intuitive setup and operation on-machine with m&h NC Gage.

This way, users can create measurement programs in HxGN NC Measure, execute the measurements through m&h NC Gage on the machine and analyse the results with the reporting and graphic functions of HxGN NC Measure.